Trintex Engineering Services

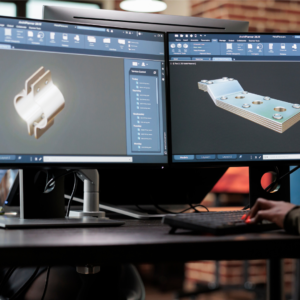

Engineering Development

We work with you in designing and optimizing new or existing products. Our team will work with you to summarize the process of reconstructing an existing object. We offer services to work from conceptual design, Modelling, and detailing.

We work on the whole product and individual parts to see how they will behave under the loads and different operating conditions. The analysis report will study and the product will be redesigned accordingly.

Talk to us to explore product design service.

Services offered:

- Concept Design

- 3D Design

- 3D scanning

- CMM inspection

- FEA and CFD

- Cost Cutting

- Stack up analysis

- Product Validation

- Data migration

- 2D drawings

- Layout drawings

- Exploded view drawings

- Pneumatic circuit drawings

Key Market Industries

Industrial

Automotive

Agriculture

Material Handeling

Mining

Sheet Metal Processing

Oil and Gas Industry

Machine Tools

SPM and Fixture

Industry Segment: Sheet Metal Processing

Location: North America

Scope:

A leading Sheet Metal Processing Machinery manufacturer in North America is looking for new segment entry of Rollforming machines to reverse engineer the machines and make value added new product. Trintex team travelled to client site, understood the requirement, made 3D scanning of products. With our unique project management, we able to design first protype within 9 weeks. Design value addition from Trintex team lead this product to fit at top in benchmarking matrix with competition

Benefits: Reverse engineering has been done with value addition to existing product.

Industry Segment: Agricultural Equipment Manufacturing

Location: West Europe

Scope:

Continuous customizations in agricultural equipment made our client to implement Trintex for efficient project execution. With multiple projects in hand, the client was looking for a dependable design team with a very short learning curve. As the in-house design team wanted to focus on the core design work, a peripheral work was given to the Trintex team.

To launch three variants customised cultivators, Trintex deploy multishift model with 3-layer quality check process. It helps client to reduce design time by 30% and thus smooth launch and handovers of product. Trintex team has make CAD automation to handle multiple variants of product at same time. Client able to handle this project now with 30-40% fewer engineering efforts.

Benefits: Engineering Development time has been reduced and product delivery is done before timeline.

Industry Segment: Coil Handling System

Location: West Europe

Scope:

Multiple quality complaint about coil handling multi-module system made our customer to initiate Engineering change project for 7 subassemblies in product.

Industry Segment: Coil Handling System

Location: West Europe

Scope:

Multiple quality complaint about coil handling multi-module system made our customer to initiate Engineering change project for 7 subassemblies in product. Axioprime team is engaged with quality errands and effectively find out root causes. Proposal has been made and validated with Static and Dynamic FEA to ensure the reliability. Approved designs has been converted into detailed design and drawings within 7 weeks of time with hybrid (onsite – by distance) module implemented by Axioprime. This was unique project as Quality improvement and cost reductions has been done at same time to beat competitors with price and quality. After design AxioPrime helps client to ERP interfaces and configurate this product with least possible inventory.

Benefits: Quality improvement and Cost reduction of product has been done effectively

team is engaged with quality errands and effectively find out root causes. Proposal has been made and validated with Static and Dynamic FEA to ensure the reliability. Approved designs has been converted into detailed design and drawings within 7 weeks of time with hybrid (onsite – by distance) module implemented by Trintex. This was unique project as Quality improvement and cost reductions has been done at same time to beat competitors with price and quality. After design Trintex helps client to ERP interfaces and configurate this product with least possible inventory.

Benefits: Quality improvement and Cost reduction of product has been done effectively